Design and Advantages

|

Other features of PC pump

|

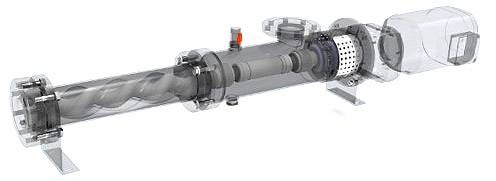

Progressive cavity pump

The pumps depends on the sealed chambers, which are formed by the interference fit between eccentric rotating rotor and stationary stator, are moved along the axial direction from pump's entry end to outlet when the rotor is rotating in the stator. Then the media within the seal chambers can be conveyed from the entry end to the outlet, thus the pump's conveyance process can be realized. Suitable for conveying the media with the following properties

|

|||||

|

|

||||||

|

Rotor Hardness can reach up to |

|

Driving Parts High Quality; Reliable manufacturers can be chosen, as SEW, Nord and ABB |

|||

|

Stator Imported from Germany; Various formulations can meet different media such as high temperature, corrosive or abrasive |

|

Shaft Seal Packing or mechanical seal; Many flushing plans can be equipped for protecting the seal system |

|||

|

Cardan Joint Various types of joint: Round pin, Cross pin, Spherical teeth joint, Hygienic joint and Flexible joint |

|

Joint Sleeve Imported from Germany; Specially for sealing of Round Pin joint, various rubber materials can be chosen |

|||

|

Spherical Teeth Joint Subtor Weifang self-developed Joint system; Transmitting greater torque while bearing higher axial force |

|||||